Introduction

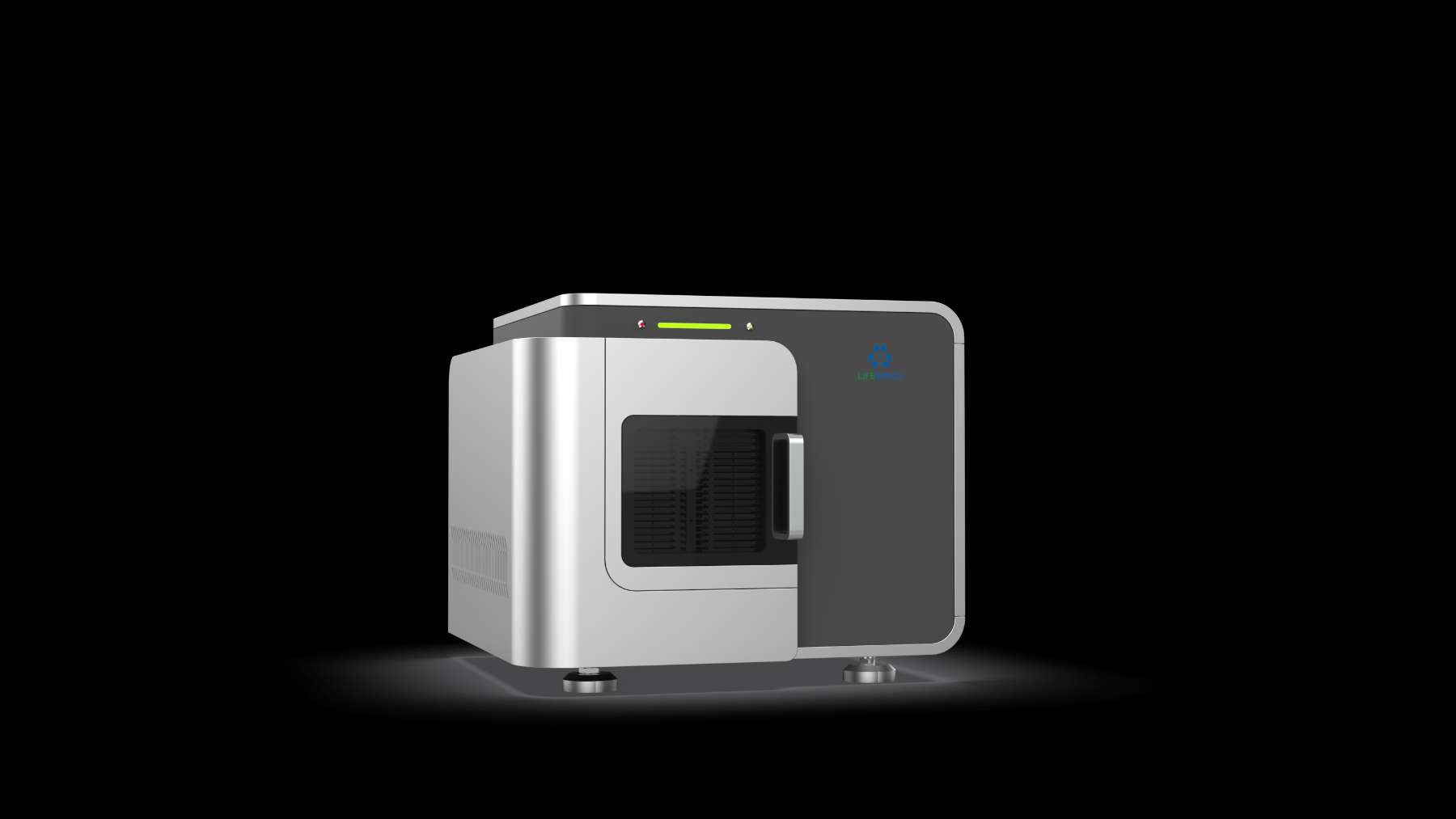

In the ever-evolving landscape of healthcare, the accurate and timely analysis of pathology samples is paramount for diagnosis and treatment. The adoption of advanced technology, particularly in the form of pathology analysis and scanning systems, has significantly improved the efficiency and precision of this critical process. However, the choice of the manufacturer for these systems is a decision that healthcare institutions must make with careful consideration. In this article, we explore the essential factors healthcare institutions should weigh when selecting a manufacturer for their pathology analysis and scanning systems.

Understanding the Healthcare Landscape

Before delving into the factors that should influence your decision, it’s crucial to appreciate the healthcare context in which pathology analysis and scanning systems operate. Healthcare institutions, ranging from hospitals to diagnostic labs, rely heavily on pathology analysis for the accurate diagnosis and treatment of patients. As technology continues to advance, there is a growing need for robust systems that can handle the demands of modern healthcare.

Identifying the Key Factors

To make an informed decision when choosing a manufacturer for pathology analysis and scanning systems, healthcare institutions should consider several key factors:

- Reliability and Reputation

- Importance of a Manufacturer’s Reputation: The reputation of a manufacturer in the healthcare industry is often a reliable indicator of their product quality and service. Well-established manufacturers with a history of delivering reliable systems and excellent customer support should be prioritized.

- Case Studies and Examples: Look for case studies and real-world examples of successful implementations of systems from the manufacturer. These can provide insights into the performance and impact of their products.

Technological Capabilities

- Assessment of Technological Innovations: Evaluate the manufacturer’s track record of technological advancements. Systems should be up-to-date with the latest innovations in pathology analysis, ensuring accuracy and efficiency.

- Compatibility with Existing Infrastructure: Consider how well the manufacturer’s systems integrate with your existing healthcare infrastructure. Compatibility is key to seamless implementation.

Regulatory Compliance

Adherence to Regulatory Standards: Ensure that the manufacturer’s systems comply with relevant regulatory standards, such as FDA approvals. This is critical for patient safety and regulatory compliance in healthcare.

- Data Privacy and Security: Assess the manufacturer’s commitment to patient data privacy and security. Healthcare institutions must prioritize the protection of patient information.

Customer Support and Training

- Availability of Customer Support: A responsive and knowledgeable customer support team is essential. In healthcare, timely assistance can be a matter of life and death.

- Training Programs: Evaluate the availability of training programs for your staff. Proper training ensures that your team can effectively use and maintain the system.

Cost Considerations

Total Cost of Ownership (TCO): Don’t just look at the upfront costs. Consider the total cost of ownership over the system’s lifespan, factoring in maintenance, upgrades, and support.

Balancing Budget Constraints: While quality is paramount, it’s also crucial to balance budget constraints with the features and capabilities offered by the manufacturer. Cost-effectiveness should be a key consideration.

Case Studies and Success Stories

To illustrate the importance of these factors, let’s explore some case studies and success stories:

- Case Study 1: A Leading Hospital’s Choice

A prestigious hospital faced the challenge of modernizing its pathology analysis capabilities. After an extensive evaluation process, they chose a well-established manufacturer with a strong reputation for reliability and accuracy. Implementing the new system significantly reduced diagnosis times, improved patient outcomes, and enhanced the hospital’s overall reputation for quality care.

- Case Study 2: A Diagnostic Lab’s Transformation

A diagnostic laboratory specializing in cancer diagnostics sought to expand its capacity. They opted for a manufacturer known for its technological innovations and seamless integration with existing systems. This choice enabled them to handle a higher volume of cases, reduce errors, and streamline their operations, ultimately leading to increased profitability.

Potential Challenges and Pitfalls

While the benefits of selecting the right manufacturer are evident, healthcare institutions must be aware of common challenges and pitfalls:

Common Mistakes to Avoid

Rushing the Decision: Hasty decisions can lead to suboptimal choices. Take the time to thoroughly evaluate manufacturers.

Ignoring Stakeholder Input: Engage stakeholders, including pathologists, IT teams, and administrators, in the decision-making process. Their insights are invaluable.

Strategies for Mitigating Challenges

Structured Vendor Assessment: Develop a structured evaluation framework that outlines your institution’s specific needs and priorities.

Cross-Functional Teams: Create cross-functional teams with representatives from different departments to ensure a comprehensive evaluation.

Site Visits and Product Demonstrations: Whenever possible, visit the manufacturer’s facilities and request product demonstrations to gain firsthand experience.

The Decision-Making Process

The decision-making process for selecting a manufacturer for pathology analysis and scanning systems involves several critical steps:

Steps in the Decision-Making Process

- Needs Assessment: Begin by conducting a thorough needs assessment to understand your institution’s specific requirements.

- Market Research: Research and compile a list of potential manufacturers, considering factors like reputation, technology, and regulatory compliance.

- Vendor Assessment: Develop an evaluation framework and assess each vendor against your criteria.

- Stakeholder Consultation: Involve key stakeholders in the decision-making process to ensure alignment with your institution’s goals.

- Site Visits and Demonstrations: Arrange site visits and product demonstrations to gain a firsthand understanding of the manufacturer’s capabilities.

- Contract Negotiation: Once you’ve identified the preferred manufacturer, negotiate contracts and agreements, ensuring clarity on pricing, support, and maintenance.

- Future Trends in Manufacturer Selection

The healthcare landscape is dynamic, and future trends will likely impact the criteria for selecting a manufacturer:

- Anticipating Evolving Needs and Technologies

- Emerging Technologies: Stay informed about emerging technologies in pathology analysis, and consider how these innovations may influence your choice of manufacturer.

- Changing Regulatory Environment: Keep an eye on evolving healthcare regulations and ensure that your chosen manufacturer can adapt to compliance requirements.

Conclusion

In conclusion, the decision to choose a manufacturer for pathology analysis and scanning systems is a pivotal one for healthcare institutions. The factors outlined in this article, including reliability, technological capabilities, regulatory compliance, customer support, and cost considerations, must be carefully considered. By prioritizing these factors and learning from successful case studies, healthcare institutions can make informed decisions that ultimately benefit patient care and the efficiency of healthcare operations.

The healthcare landscape continues to evolve, and as technology advances, healthcare institutions must remain vigilant and adaptable in their selection of manufacturers to ensure they meet the ever-changing needs of patients and providers alike.